CFD-DEM simulation (left)

This video shows a CFD-DEM simulation of a blast furnace, a device heavily used for the production of hot metal. Typically, the material is added to the furnace in layers, and hot blast is added through the tuyeres.

DEM simulation (right)

This second video, shows a pure DEM simulation of the charging phase. The setup on the left uses spherical particles and accounts for the non-sphericity with a rolling friction model. The setup on the right uses multi-spheres for a more realistic representation of the non-spherical particles.

By loading the video, you agree to Vimeo's privacy policy.

Learn more

Circulating fluidized beds are of high importance in chemical, plastic and steelmaking industries. Cyclong separators are also common in household vacuum cleaners.

This coupled CFD-DEM simulation shows that most of the particles are captured by the first cyclone, while some single particles can escape and are captured by the second cyclone. Velocities of fluid phase and particle phase are depicted in the left and center contour plots, respectively.

By loading the video, you agree to Vimeo's privacy policy.

Learn more

An extruder is transporting and melting polypropylene granules (particles: white spheres, molten plastic: purple iso-surfaces). The interplay between solid, air and liquid is obtained by coupling Aspherix with cfdemSolverInterDyMPC. The melting is reproduced by a mass transfer from solid to liquid, which occurs when the particle temperature exceeds the melting point due to external heating.

By loading the video, you agree to Vimeo's privacy policy.

Learn more

This video shows a model of a rotary cooler, realized with CFDEM®coupling. A hot particle stream enters through a transfer chute into the slightly inclined and rotating cooler. Gas streams from right to left through the cooler. While the particles get cooled, the gas is heating up. The final product exits the cooler at the desired temperature.

By loading the video, you agree to Vimeo's privacy policy.

Learn more

This video shows a full-coupled CFD-DEM simulation of a fluidized bed granulation process. A liquid-solid mixture is sprayed into the granulator (see droplets in magenta) from a nozzle. The liquid and solid species are deposited onto the carrier particles and, partially, onto the granulator walls. The product quality (between 0 to 1) measures the coating/granulation level of the carrier particles. Finally, the temperature field changes dynamically due to the heating from the fluidization air and the cooling due to the liquid evaporation.

By loading the video, you agree to Vimeo's privacy policy.

Learn more

A spray wets the inserted particles. Both the walls and a hot gas stream heat up the particles which triggers evaporation. The water vapor is transported by the fluid.

By loading the video, you agree to Vimeo's privacy policy.

Learn more

By loading the video, you agree to Vimeo's privacy policy.

Learn more

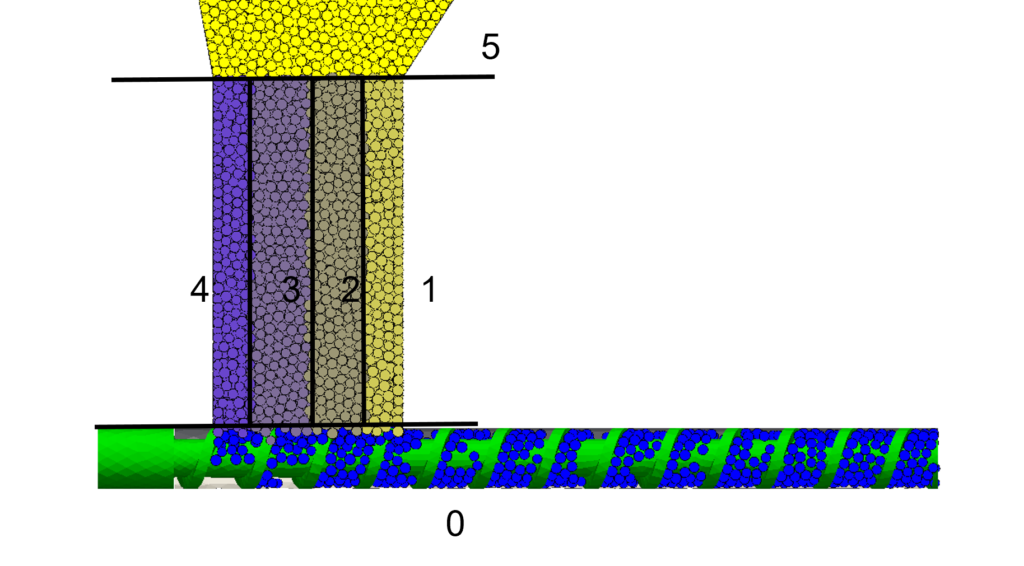

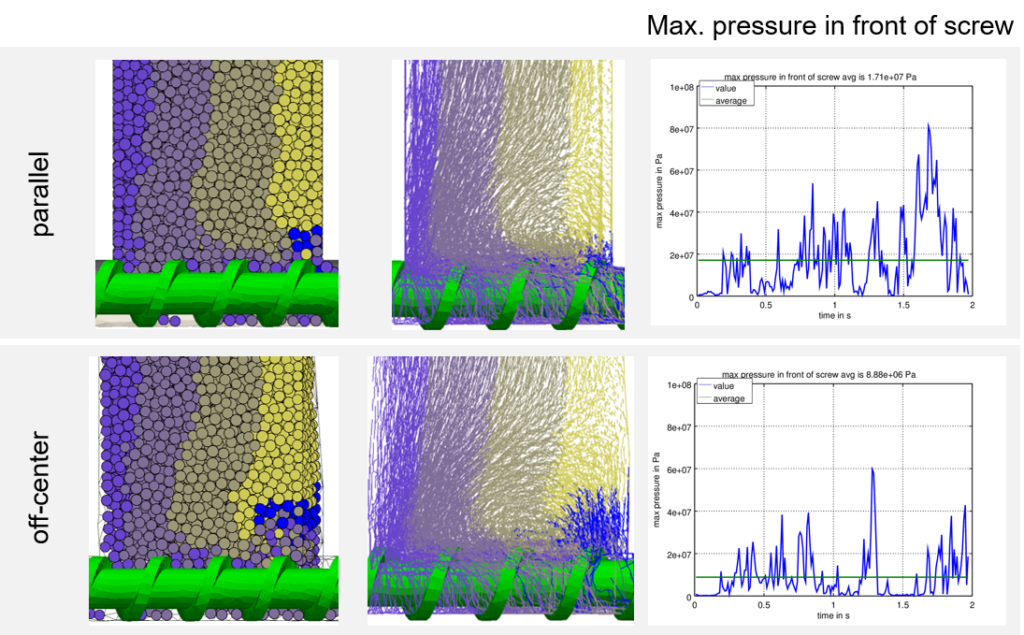

Two screw conveyor geometry designs are compared (symmetric and off-centered)

When the screw starts to move, the particles are colored according to their horizontal position:

Using Lagrangian particles for spray coating of a moving meshed object.

By loading the video, you agree to Vimeo's privacy policy.

Learn more

In this video, CFDEMcoupling is used to simulate the fluid and particle dynamics in a ball mill. The solver couples a Volume of Fluid (VOF) CFD solver with Aspherix™.The rotor (in grey) is enclosed into a cylindrical drum (transparent) containing particles and two fluids: water and air. At the beginning of the simulation, the liquid fills the lower part of the ball mill and the particles are immersed in it. As it moves, the rotor displaces the liquid, which in turn drags the particles away from the bed.

By loading the video, you agree to Vimeo's privacy policy.

Learn more

Simulation of spray-coating in a fluidized bed, often used to add active or inactive ingredients or to coat particles. The fluidized bed is simulated using CFD-DEM, additionally the spray is fully resolved in a Lagrangian way (subject to fluid forces). Particles then capture the spray and get wetted. Optionally, particles can transfer the liquid content from one to another, and the particle-particle interaction laws can be extended by e.g. liquid bridge forces.

By loading the video, you agree to Vimeo's privacy policy.

Learn more

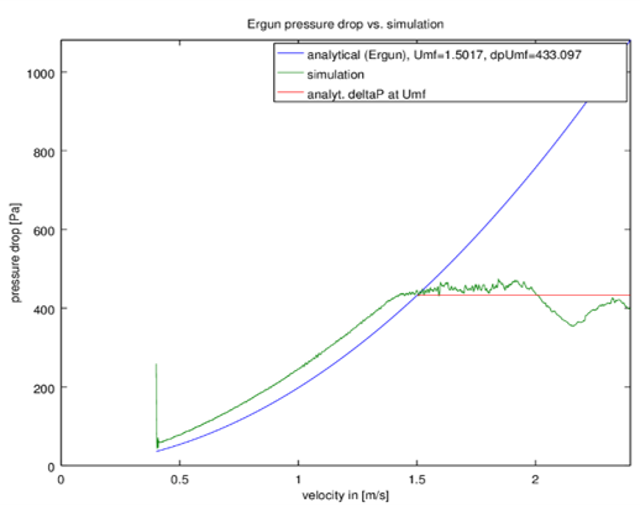

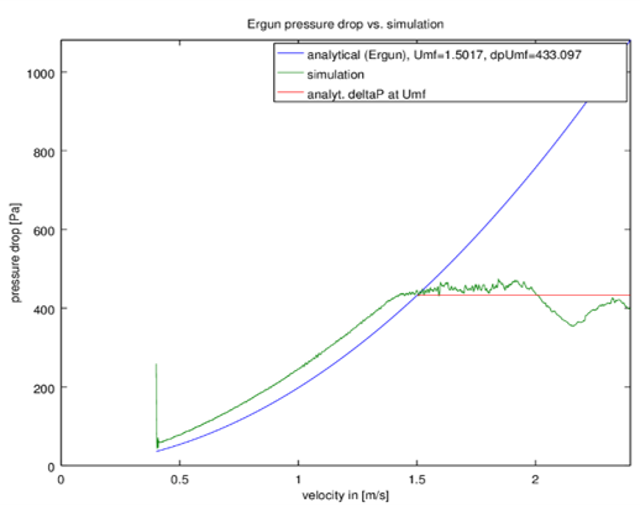

Coupled CFD-DEM simulation of the fluidization of elongated blocky particles. The particle shape is resolved using a superquadric shape model. The graph shows the comparison between simulation and analytical data.

By loading the video, you agree to Vimeo's privacy policy.

Learn more

This application case combines numerous functionalities:

By loading the video, you agree to Vimeo's privacy policy.

Learn more

Moist particles are heated up by warm flow. This leads to a drying of the particles.

By loading the video, you agree to Vimeo's privacy policy.

Learn more

CFD-DEM simulation (left)

This video shows a CFD-DEM simulation of a blast furnace, a device heavily used for the production of hot metal. Typically, the material is added to the furnace in layers, and hot blast is added through the tuyeres.

DEM simulation (right)

This second video, shows a pure DEM simulation of the charging phase. The setup on the left uses spherical particles and accounts for the non-sphericity with a rolling friction model. The setup on the right uses multi-spheres for a more realistic representation of the non-spherical particles.

By loading the video, you agree to Vimeo's privacy policy.

Learn more

Circulating fluidized beds are of high importance in chemical, plastic and steelmaking industries. Cyclong separators are also common in household vacuum cleaners.

This coupled CFD-DEM simulation shows that most of the particles are captured by the first cyclone, while some single particles can escape and are captured by the second cyclone. Velocities of fluid phase and particle phase are depicted in the left and center contour plots, respectively.

By loading the video, you agree to Vimeo's privacy policy.

Learn more

An extruder is transporting and melting polypropylene granules (particles: white spheres, molten plastic: purple iso-surfaces). The interplay between solid, air and liquid is obtained by coupling Aspherix with cfdemSolverInterDyMPC. The melting is reproduced by a mass transfer from solid to liquid, which occurs when the particle temperature exceeds the melting point due to external heating.

By loading the video, you agree to Vimeo's privacy policy.

Learn more

In this video, CFDEMcoupling is used to simulate the fluid and particle dynamics in a ball mill. The solver couples a Volume of Fluid (VOF) CFD solver with Aspherix™.The rotor (in grey) is enclosed into a cylindrical drum (transparent) containing particles and two fluids: water and air. At the beginning of the simulation, the liquid fills the lower part of the ball mill and the particles are immersed in it. As it moves, the rotor displaces the liquid, which in turn drags the particles away from the bed.

By loading the video, you agree to Vimeo's privacy policy.

Learn more

Simulation of spray-coating in a fluidized bed, often used to add active or inactive ingredients or to coat particles. The fluidized bed is simulated using CFD-DEM, additionally the spray is fully resolved in a Lagrangian way (subject to fluid forces). Particles then capture the spray and get wetted. Optionally, particles can transfer the liquid content from one to another, and the particle-particle interaction laws can be extended by e.g. liquid bridge forces.

By loading the video, you agree to Vimeo's privacy policy.

Learn more

Coupled CFD-DEM simulation of the fluidization of elongated blocky particles. The particle shape is resolved using a superquadric shape model. The graph shows the comparison between simulation and analytical data.

By loading the video, you agree to Vimeo's privacy policy.

Learn more

This application case combines numerous functionalities:

By loading the video, you agree to Vimeo's privacy policy.

Learn more

Moist particles are heated up by warm flow. This leads to a drying of the particles.

By loading the video, you agree to Vimeo's privacy policy.

Learn more