Simulate Particle Dynamics Effortlessly

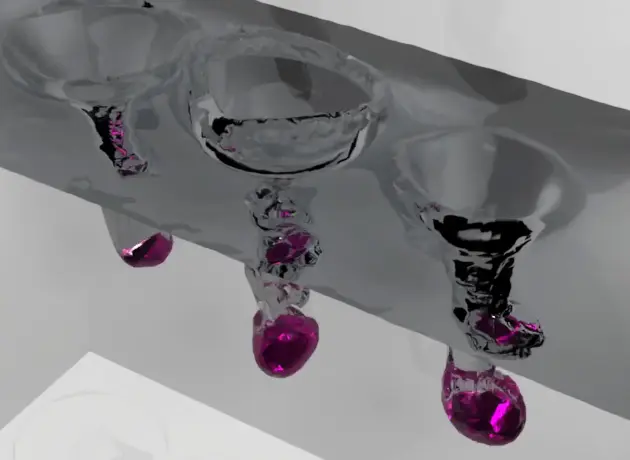

Aspherix® is a state-of-the-art Discrete Element Method (DEM) software that provides comprehensive simulation tools for a wide range of applications.

Aspherix®

Aspherix® enables accurate modeling of particle behavior across diverse applications, providing key insights into complex processes. With advanced coupling capabilities, Aspherix® ensures reliable predictions, helping users optimize their operations and drive innovation.

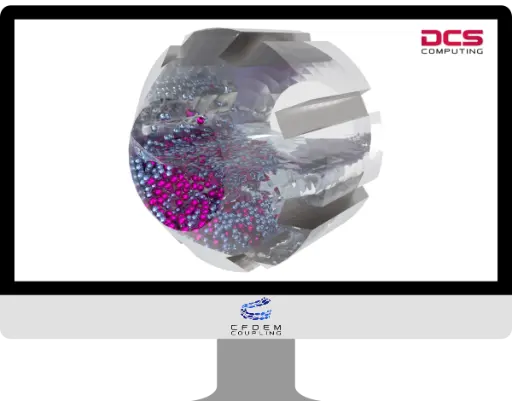

CFDEM®coupling

CFDEM®coupling is a state-of-the-art simulation platform that integrates DEM and CFD technologies to provide a comprehensive view of particle-fluid interactions. This powerful coupling tool enhances your ability to model complex systems, optimize processes, and innovate new solutions across various industries.

Why DCS

Our goal is to provide software that meets our customers’ needs in the best possible way.

This requires flexibility at many levels. We provide it with the following four points:

Flexible Licensing

Lease or perpetual – you choose!

Tailored Solutions

Custom developments & workflows.

Multi-Platform

Free choice of operating system.

Rapid Deployment

Benefit from two major releases a year.

References

Explore Our Features

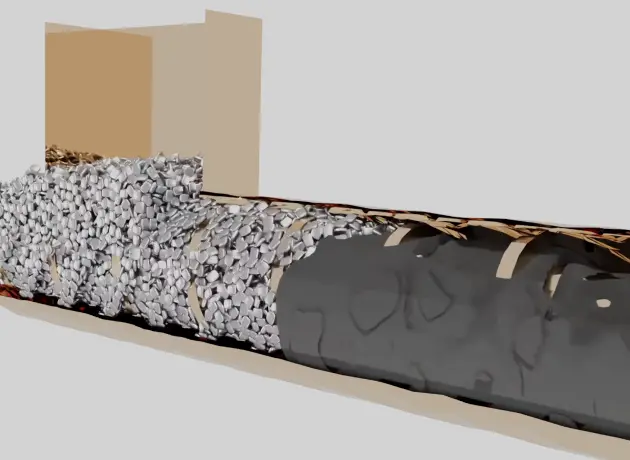

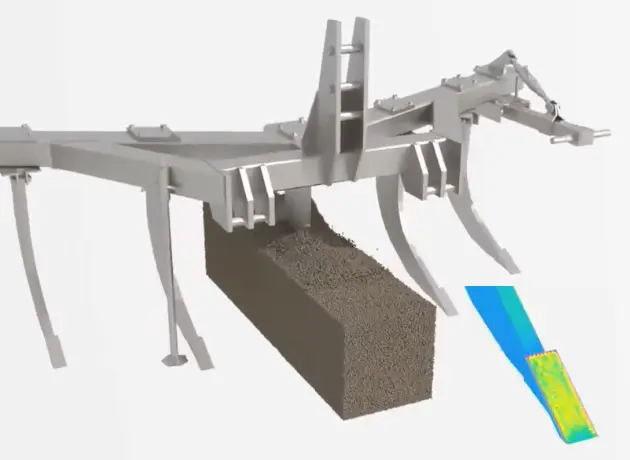

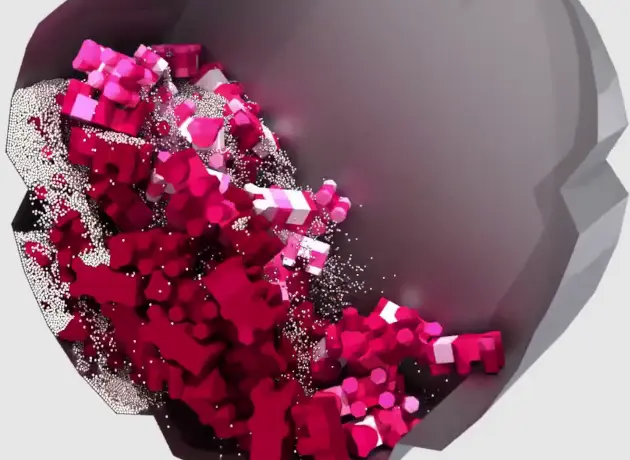

Click through our range of case studies below to find out how Aspherix® and CFDEM®coupling is applied to effectively support simulations in various industries.

Advanced coarsegraining & load balancing

Phase change & chemical reactions

Wear modeling & attrition

Complex geometry motion & 6dof solver for meshes

Solid & liquid coating & powder handling

Coupling interfaces: CFD, FEM, API

Ready to unlock the full potential of Aspherix®?

Request your free 4-week trial, complete with a user-friendly GUI, 16 parallel licenses, and a step-by-step video tutorial to get started!

Blog Articles

Our newsletter is just like particle simulation – full of dynamic insights.

We'd love to stay connected ...

... subscribe to our newsletter and get the latest infos about projects and releases firsthand!