The animation shows the flow of 5 micron sized evaporating droplets flowing through the nasal airways during a respiration cycle using Aspherix® DEM software. The air flow information is pre-calculated using CFD and the transient flow field is imported to Aspherix®.

By loading the video, you agree to Vimeo's privacy policy.

Learn more

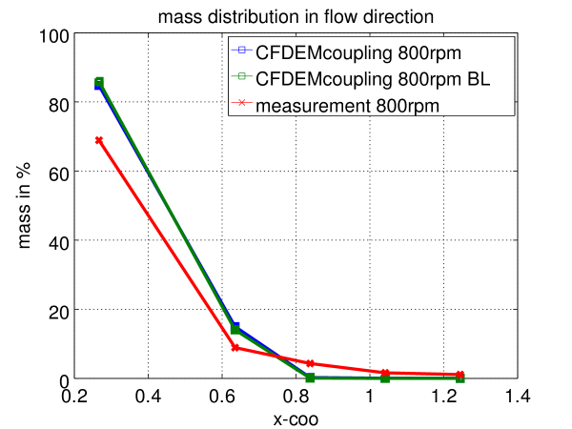

Simulation of the die filling process for cohesive and non-cohesive material. This setup can be used to investigate the material segregation, emerging inhomogeneities in the bulk material or the permissible operation speed.

By loading the video, you agree to Vimeo's privacy policy.

Learn more

By loading the video, you agree to Vimeo's privacy policy.

Learn more

Coupled CFD-DEM simulation where soft and stiff fibers are inserted into a mold. The soft fibers get deformed and, in a second moment, get back to the original shape, wile the rigid fibers maintain their shape.

By loading the video, you agree to Vimeo's privacy policy.

Learn more

Animation of simulation with one-way CFD-DEM with MRF

By loading the video, you agree to Vimeo's privacy policy.

Learn more

Create custom shapes using bonded particles.

1.Bond breakage criterion

2.Normal and tangential

stiffness of the bonds

3.Energy dissipation of

the bonds

4.Properties of the spherical

particles

By loading the video, you agree to Vimeo's privacy policy.

Learn more

Cylinder breakage on impact

This video shows a cylinder impacting onto flat rigid wall for three material impact strengths. The cylinder is made by bonded spherical particles and the strength of the bonds (which increases from left to right) affects the impact strength of the material.

Shape effect – multispheres vs spheres:

By loading the video, you agree to Vimeo's privacy policy.

Learn more

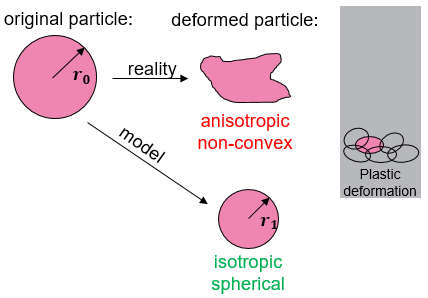

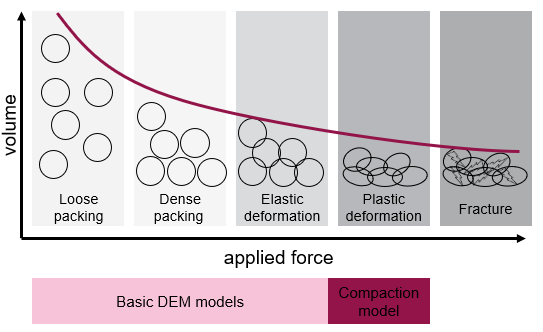

Powder compaction is the extension of Aspherix® towards high plastic deformation. For powders, we need a model that is valid all the way from “fluffy agglomerates” to densified tablets.

By loading the video, you agree to Vimeo's privacy policy.

Learn more

By loading the video, you agree to Vimeo's privacy policy.

Learn more

This video shows a flexible membrane that consists of spherical particles. This is a specific application case of a cohesion model.

By loading the video, you agree to Vimeo's privacy policy.

Learn more

Interaction between granular material and a deformable chute.

By loading the video, you agree to Vimeo's privacy policy.

Learn more

Coupled CFD-DEM simulation of particles in a complex, time-varying geometry. For this purpose, an Immersed Boundary Method (IBM) solver has been coupled with Aspherix®. The IBM, in contrast to traditional finite volume method, allows to solve the flow in interlocking geometries.

By loading the video, you agree to Vimeo's privacy policy.

Learn more

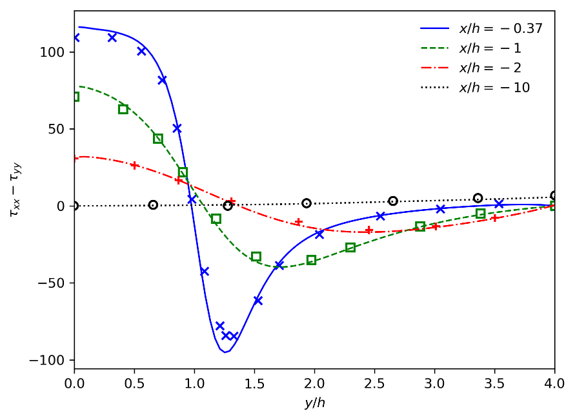

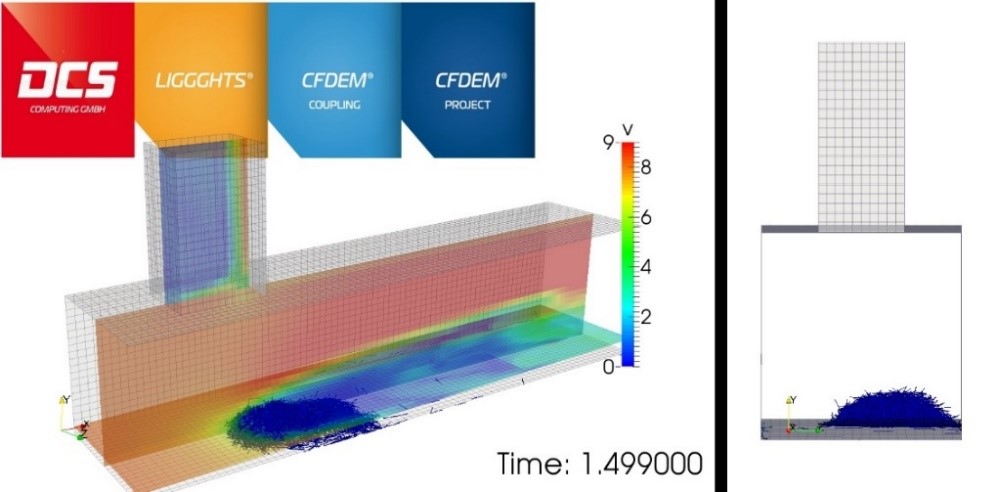

This fully four-way coupled CFD-DEM simulation with CFDEM®coupling shows the flow of a viscoelastic fluid and particles through a contraction. The viscoelasticity of the fluid is modelled by the Giesekus equations.

The graph shows the validation against literature (Favero et al.).

By loading the video, you agree to Vimeo's privacy policy.

Learn more

Multi-spheres (MS) coupled to CFD preserving correct particle mass and hydraulic diameter for poly-disperse MS mixtures.

By loading the video, you agree to Vimeo's privacy policy.

Learn more

This video shows a coupled CFD-DEM simulation of settling fibers. The fibers are modelled as multi-spheres.

Aspherix® and CFDEM®coupling can be applied to different aspects of battery modelling. Find below examples for modelling the electrical conductivity within a battery, its heating due to the change of the packing density, the simulation of a thermal runaway as well as the depiction of the drying process of a Li-ion battery with resolved-unresolved CFD-DEM.

The design of future battery materials is a big challenge, and the battery performance strongy depends on the packing properties. In the below animation we model the paste as particles in an electric potential. The material experiences heating due to the electric current.

By loading the video, you agree to Vimeo's privacy policy.

Learn more

This simulation shows a lithium-ion cell between two horizontal electrodes at different potentials.

The top electrode moves downwards two times to simulate compression of the battery pack due to impacts. As the distance between the two electrodes decreases, the electric current flowing through the cell increases (see top inset). A stronger current implies a higher Joule heating and, therefore, the reaching of higher temperatures in the cell (see top inset).

By loading the video, you agree to Vimeo's privacy policy.

Learn more

During a thermal runaway of a Li-Ion battery hot gas exits the battery and burns. Using CFD we investigate the propagation of the flame front, velocities and pressures occurring during such an event.

By loading the video, you agree to Vimeo's privacy policy.

Learn more

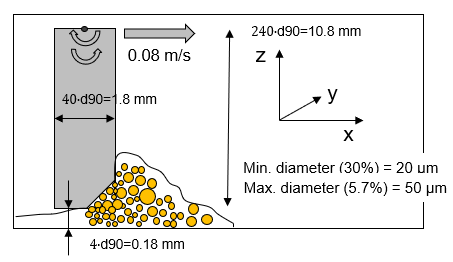

A large size difference between active material and carbon black requires using resolved and unresolved CFD-DEM at the same time.

The hybrid resolved-unresolved CFD-DEM simulation of the drying process of Li-Ion battery electrodes reveals high dynamics and segregation although the process is very slow.

The left side of the animation shows that large particles are represented using resolved CFD-DEM. The small particles are modelled using unresolved CFD-DEM.

By loading the video, you agree to Vimeo's privacy policy.

Learn more

Size-based Segregation of Pharmaceutical Powders

This is the CFD-DEM simulation of fine, poly-disperse pharamaceutical powder in a closed tube. Size segregation is caused by the counter-current airflow which is induced by the particle stream falling downwards.

By loading the video, you agree to Vimeo's privacy policy.

Learn more

Size-based Segregation of Pharmaceutical Powders

This is the CFD-DEM simulation of fine, poly-disperse pharamaceutical powder in a closed tube. Size segregation is caused by the counter-current airflow which is induced by the particle stream falling downwards.

By loading the video, you agree to Vimeo's privacy policy.

Learn more

Size-based Segregation of Pharmaceutical Powders

This is the CFD-DEM simulation of fine, poly-disperse pharamaceutical powder in a closed tube. Size segregation is caused by the counter-current airflow which is induced by the particle stream falling downwards.

By loading the video, you agree to Vimeo's privacy policy.

Learn more

Size-based Segregation of Pharmaceutical Powders

This is the CFD-DEM simulation of fine, poly-disperse pharamaceutical powder in a closed tube. Size segregation is caused by the counter-current airflow which is induced by the particle stream falling downwards.

By loading the video, you agree to Vimeo's privacy policy.

Learn more

Size-based Segregation of Pharmaceutical Powders

This is the CFD-DEM simulation of fine, poly-disperse pharamaceutical powder in a closed tube. Size segregation is caused by the counter-current airflow which is induced by the particle stream falling downwards.

By loading the video, you agree to Vimeo's privacy policy.

Learn more

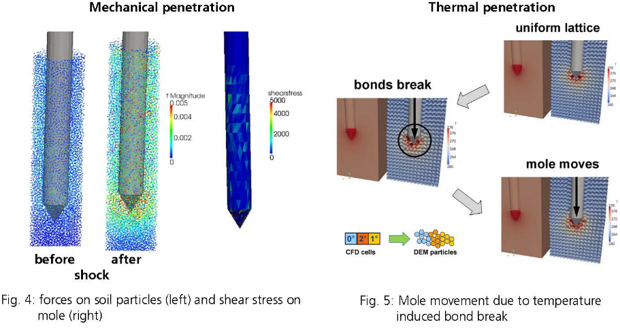

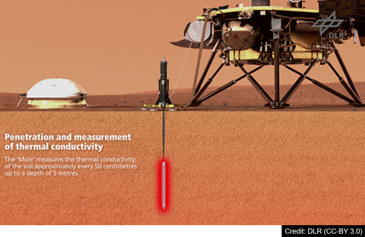

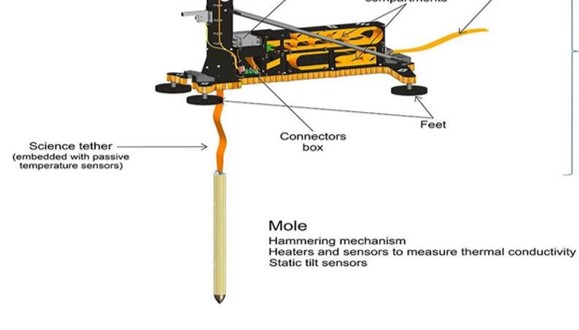

The mole is about 30 cm in the regolith and probably still 7 cm in the tube of the support structure. It is approximately pointing 15° away from the vertical and has undergone either some rotation or precession of its rotation axis. It is still healthy but, of course, Its life time is limited.

Publication DLR with Goniva & Kloss 2011

Grosse, Lange, Burrow, van Zoest, Goniva, Kloss, (2011) First Design Concept for a Combined Thermal and Mechanical Penetration Device for Investigations of Icy Planetary Bodies – The ‘Cryo-Mole’. EGU General Assembly 2011, Wien, Österreich.

Modelling of the wave attenuation by flexible vegetation. Due to the flow resistance caused by the vegetation the wave pattern as well as the erosion pattern on the bottom is affected.

By loading the video, you agree to Vimeo's privacy policy.

Learn more

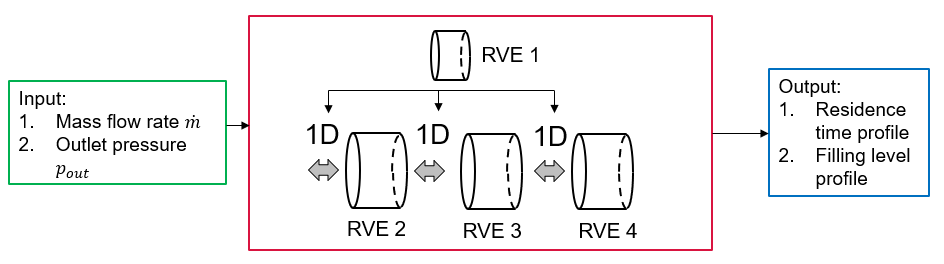

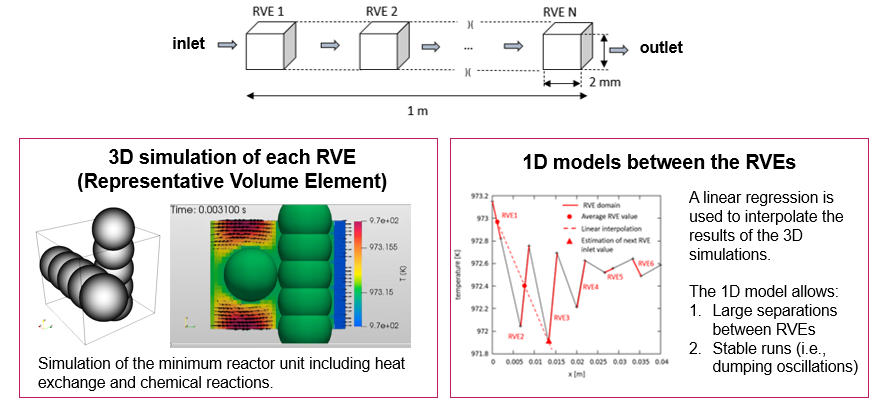

Process times and system size are often an issue when modelling industrial applications with a high degree of resolution. To overcome these limitations we have developed a mixed 1D-3D model, in this case applied to a twin-screw exruder case. The approach consists of two parts:

This is a sketch of the scheme:

In this project we are investigating the effect of powder cohesiveness on the quality of the particle bed.

A rigid recoater moves forward and ocillates to account for external vibrations (e.g., induced by the machine, imagect with the printed objects, …).

With the current cohesion settings, occasional defects occur, caused by particle jamming.

By loading the video, you agree to Vimeo's privacy policy.

Learn more

Heating of a parabolic mirror due to laser reflection. The laser beam is modelled by distinct photons.

By loading the video, you agree to Vimeo's privacy policy.

Learn more

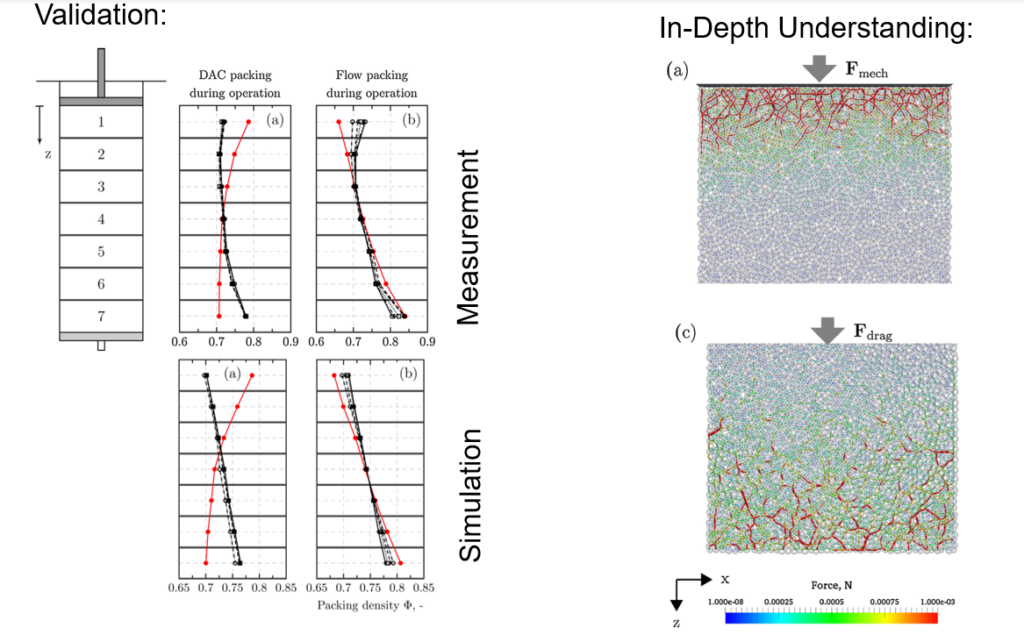

The group of Prof. Weuster-Botz at TUM (D. Hekmat, M. Dorn) showed impressive scientific progress on modelling chromatography columns:

“…packing non-uniformity may cause peak asymmetry and limit the performance of packed-bed chromatographic columns.”

“Using coupled CFD-DEM modeling, the measured packing behavior was reproduced qualitatively providing valuable information regarding intrinsic packing properties that up to now have been inaccessible.”