Particle Template Based Coarse Graining

Aspherix® now offers local coarse-graining, allowing users to define coarse-graining settings individually for each particle template. This flexibility supports more accurate and efficient simulation of systems with mixed particle types. In CFDEM®coupling, drag models and heat transfer models (such as LaEuScalarTemp) can now directly use this particle-specific coarse-graining information during calculations, improving the physical accuracy of coupled CFD-DEM simulations.

The animation shows a large fluidized bed simulation where particle segregation occurs between two particle types: large particles with a primary radius of 5 mm (no coarse-graining applied) and smaller particles with a primary radius of just 0.05 mm, coarse-grained by a factor of 100 to achieve an effective parcel radius of 5 mm.

This setup showcases the new capability to combine coarse-grained and non-coarse-grained particles within the same simulation, enabling large-scale, detailed modeling without compromising performance.

More Accurate Voidfraction Model

A new voidfraction model has been introduced, based on decomposing CFD cells into tetrahedrons. This approach distributes particle volume more accurately into neighboring cells, creating an inherent smoothing effect that leads to smoother gradients and time derivatives, as well as improved simulation stability.

The method also inherently respects processor (horizontal plane in animation) and cyclic boundaries, enhancing conservation and consistency across parallel computations.

Improved Stability for Heat Transfer Models

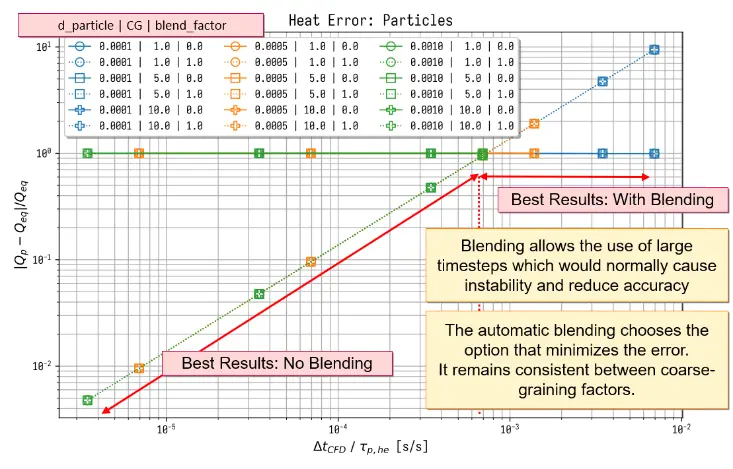

Temperature blending for heat transfer calculations now includes automatic determination of the blend factor, which is computed individually for each particle.

This per-particle approach ensures the blend factor is applied only when necessary, enhancing accuracy and efficiency in thermal simulations.